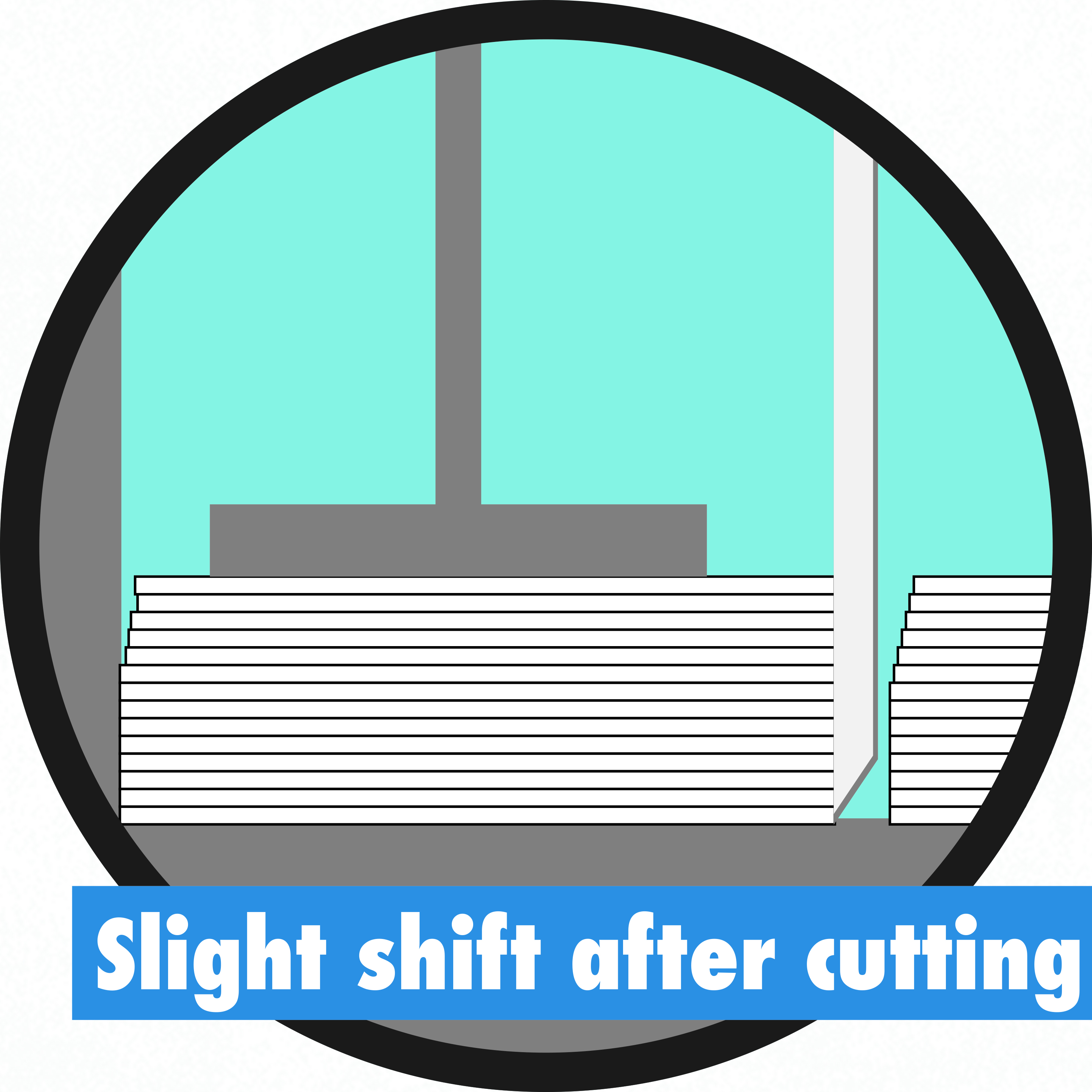

To speed the printing process we use a machine like this to cut many sheets at the same time. During the process the sheets may shift so it's very common that any border designed too close to the cutting line will look uneven in the printed product.

.

Because of this, we highly recommend that you don't design with borders and if you do, make sure they are at least 1/4" inside the trim zone or 3/8" inside the bleed zone. However, we still can't assure the borders will be even. For example:

Incorrect: Here the border is at less than 1/4" inside from the trim zone or at 3/8" inside from the bleed zone.

Correct: Here is what your file, including the bleed should look like for the best results. The border is at least 1/4" inside from the trim zone or at least 3/8" inside from the bleed zone.

Thin borders may look uneven. The thicker the border, the better it will look.

Our cutting tolerance is 1/32 of an inch at either side for a total visual effect of 1/16.

If we cut business cards one at a time, our name would not be PrintDirtCheap

Here's a video showing how this problem occurs:

Why are borders sometimes uneven on printed jobs? from PrintDirtCheap.com on Vimeo.